After years of dominance, 3D printing technology has matured and is being in utilization to rapidly develop and produce equipment in response to the present COVID-19 outbreak. Although 3D printing technology fields have grown increasingly economical and popular in recent years. The method dates back to the 1980s when the first advanced manufacturing equipment was produced.

The technique of transforming digital plans into three-dimensional solid things by piling advanced substances on top of one another is commonly known as 3D printing. Organizations may use it for small-scale prototypes at the planning stage. However, some may use it to build tools or architect features, and yet others may choose to conduct the entire end-to-end design process through 3D printing.

Here are some of the most innovative 3D printing applications to date.

What will you see here?

3D printing technology in Aerospace field

SYS Systems, a UK firm, has been delivering 3D printing solutions to various sectors, beginning with aerospace.

It makes sturdy and durable plastic 3D models with fire-resistant qualities required for Aerospace safety using Fused Deposition Modelling (FDM).

According to SYS Systems, FDM technology provides thermoplastic that is temperature, UV, chemical, and environmental resistant.

3D printing technology in Healthcare

3D printing technology is transforming healthcare, and solutions are being used across the UK to adapt quickly to the problems posed by the COVID-19 epidemic.

Ricoh 3D, a Telford-based business, said it would provide 40,000 3D-printed face shields to NHS personnel each week to keep them safe from COVID-19. The 3D-printed shields, according to the industry, will provide a reusable solution while also lowering long-term expenditures.

Other 3D-printing firms assisting public health organizations include startups like Edumaker and Tocabot, which set out to address the shortage of Personal Protective Equipment (PPE) for healthcare professionals.

On the opposite end of the spectrum, business giant IBM unveiled an employee-led effort to develop 3D-printed face visors for healthcare workers. Initially, 20 visors were supplied to personnel at University Hospital Southampton, and over 300 visors have since been created and distributed.

The visors are three parts: a 3D-printed frame, an acetate sheet, and a stretchy strap to hold the frame together. Initially, IBM employees used their development materials, but they have recently requested funds for mass manufacturing through GoFundMe.

Before the epidemic, the NHS began testing 3D-printed prosthetic hands for children in 2017 in collaboration with Open Bionics, a Bristol-based business.

The usage of 3D printing for prostheses results in lighter designs and cheaper prices, from up to £60,000 to £5,000 utilizing a 3D printer.

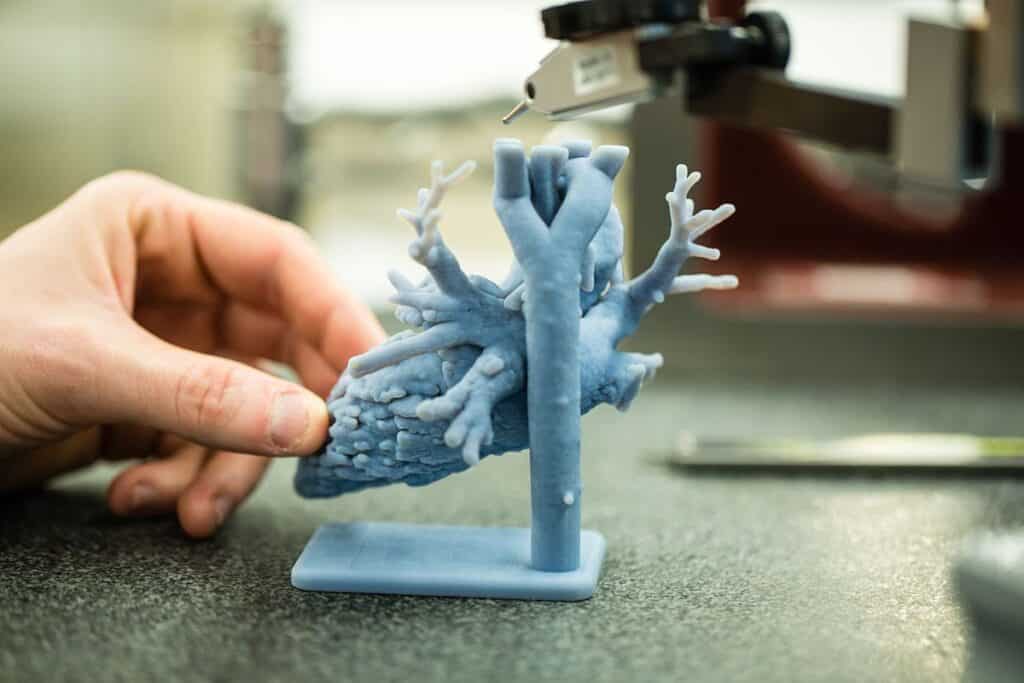

As a 3D model may come in handy in the pre-planning phase of difficult surgery, surgeons can also get assistance with the help of 3D printing technology when planning to do a transplant. Guy’s and St Thomas’ NHS Foundation Trust was the first to use Stratasy’s multi-material 3D printing technology to do this.

3D printing technology in Aviation

3D printing has created several possibilities in the aviation field and manufacturing sectors. With many well-known companies taking advantage of the technology.

The technology has found a place in aviation production, with Finnair, for example, using 3D printing for small-batch manufacture in its Airbus A320 aircraft.

With the inclusion of lattices inside the panels, the airline has integrated 3D printed spacer panel pieces into its cabins to fill in overhead storage spaces.

Siemens, a German industrial manufacturing giant, announced a £27 million investment in Worcester. With the goal to establish the UK’s largest 3D printing facility in collaboration with Material Solutions. The plant, which will investigate 3D printing in aviation, is expected to employ more than 50 people as Siemens prepares to embrace the expansion of additive manufacturing.

3D printing technology in Fraud Prevention

3D printing technology is showing promise in reducing card-present fraud in applications such as point-of-sale systems and ATMs. Banks, for example, are increasingly employing 3D printing to create ATM parts that prevent credit card skimmers. After the physical and digital security worlds collide. 3D printing will play a critical role in the development of hardware to combat fraud.

Engineering

In a variety of ways, 3D printing has had a significant influence on the engineering business.

Williams F1 of the United Kingdom employs 3D printing to make some of the parts of its racing vehicles. Also pieces for prototypes for testing in wind tunnels. The technology reduces the timeframe for part creation, allowing for a faster reaction on how well features perform.

In 2017, BT also began testing 3D printing as a means of fast turning technical concepts into reality. Costs for prototype equipment such as a cable threading needle for making it easier to connect new circuits in a roadside cabinet and a vibrating bullet for transporting fiber into houses reduces by the telco.

3D printing technology in Automotive fields

The use of 3D printing technology revolutionize vehicle construction in the automobile sector.

‘Strati,’ an electric automobile produced by Local Motors that has been billed as the “world’s first 3D-printed electric car”. At the 2014 International Manufacturing Technology Show in Chicago. The automobile was printed in 44 hours using a large-scale 3D printer.

MINI announced a 3D printing customization service in 2018 to allow clients to design their own automobile components such as door handles or side plates. Professionals prints and customize the parts in collaboration with Carbon, EOS, and HP.

Divergent has also created a revolutionary technique for vehicle production that includes 3D-printed joints. This method, dubbed ‘Node,’ consists of 3D-printed aluminum nodes that subsequently join with 3D-printed carbon fibers.

Using this method, the firm created the ‘Blade’ supercar and ‘Dagger’ motorbike.

3D printing technology in Education

3D printing has increased creativity and problem-solving in schools.

Students can use 3D printing in fields such as engineering to print out concepts; demos of this are already been in implementation at several universities across the world.

In 2013, the UK government established a 3D printer program to improve STEM education. Following the announcement, the software tests in 21 different schools.

Since then, secondary and elementary schools using 3D printing technology to allow pupils to create and test their own products in real life.

In 2014 comes the ‘CREATE’ education initiative in the United Kingdom. With the goal to assist schools in integrating 3D printing into the curriculum by providing instructors with materials, lesson plans, and presentations.

Conclusion

3D printing is still making waves in a wide variety of areas, from healthcare to art to research. Although 3D printing appears to be a very future technology, it has been around since the 1980s. The early days were fraught with rejections and failures, as patents and ideas frequently failed to secure the required finance.

It is now a complex procedure that has gained appeal because of its quickness and low cost. It’s especially promising for smaller businesses that can compete with larger corporations. Which is by taking advantage of fast manufacturing at a cheaper cost. Print by print, 3D printing technology is actually altering the world.

Read More!

- Get these smart rings and make your life more updated and comfortable!

- How to check the mouse sensitivity by DPI? Check if you are a gamer!

- How do fix common printer problems?

- Now you can create and convert 3D photos on your iPhone!