Hello and welcome to the world of 3D printing! In this blog, we will explore the fascinating world of wood 3D printer filaments. These are special filaments that give your 3D prints the appearance of real wood. Whether you are new to 3D printing or an expert, we’ve got you covered. Essentially, 3D printing is the process of manufacturing objects layer by layer using a special printer. Adding the warmth and feel of wood to your work can elevate it to the next level. That’s where wood 3D printer filaments come in! This blog is intended to be easy to understand for everyone, regardless of their level of technical knowledge.

We will take you on an enjoyable journey through the fundamentals of wood 3D printer filaments without using jargon. We’ll also look at some of the best wood 3D printer filaments available in the market so that you can easily add a touch of nature to your 3D prints. Let’s get started and make your work stand out with the timeless appeal of wood!

What will you see here?

Know more about wooden 3D Printer Filament

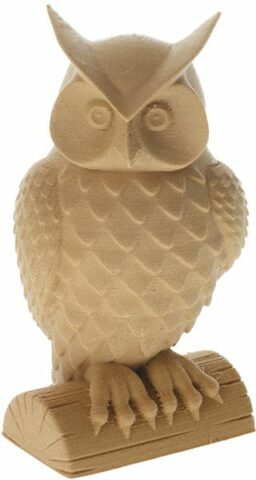

3D Wood Printer Filament is a material used in 3D printing, which creates three-dimensional objects layer by layer. Unlike standard 3D printing plastics, the wood filament is made from a mix of wood particles or fibres and a basic plastic ingredient, mostly PLA. However, the combination of wood and plastic gives the filament distinct qualities. Though that closely resembles the appearance and, to some extent, feel of real wood.

This wood-infused filament enables enthusiasts and producers to create 3D prints with a hardwood texture and look. They are giving their designs a natural and organic feel. The prints can range from decorative pieces to useful prototypes by combining the flexibility of 3D printing with the aesthetic attributes of wood.

Amolen Wood PLA

Amolen Wood PLA is a high-quality 3D printer filament that smoothly combines PLA's user-friendliness with the true look and feel of real wood. This filament, made from a combination of PLA and finely ground bamboo, has a distinct wood grain texture and even a slight, pleasant wood-like aroma. Amolen Wood PLA prints easily and behaves similarly to normal PLA. With a recommended printing temperature range of 190-220°C, it is suitable for most FDM 3D printers. The printed models, which come in a variety of wood tones like walnut, mahogany, and natural, have a stunningly accurate wood grain feel and may be further customized by staining or painting.

The filament's surface has the roughness of actual wood, creating an authentic tactile feel. Sanding is an alternative for those who prefer a smoother finish, but take care not to damage the unique wood grain. Amolen Wood PLA is strong and durable, comparable to normal PLA, making it suited for a wide range of printing projects. Amolen Wood PLA not only performs admirably, but it also contributes to environmental sustainability. Made from biodegradable components, it is an environmentally friendly alternative to traditional wood, meeting the growing demand for sustainable 3D printing solutions. In summary, Amolen Wood PLA emerges as a standout choice among 3D wood filaments. Its simplicity in printing, authentic wood-like appearance, and eco-friendly composition make it a top contender for those seeking to bring a touch of nature to their 3D-printed creations.

ColorFabb WoodFill

ColorFabb WoodFill is an outstanding 3D printer filament, combining 70% PLA with 30% recycled wood fibers to produce prints that authentically resemble real wood. With a natural wood look, slight wood grain, and light wood scent, WoodFill offers a unique aesthetic. While slightly less strong than PLA, it remains sturdy for various applications and is more flexible than standard PLA. Although presenting a moderate printing challenge, especially requiring a larger nozzle and adjusted flow rate, WoodFill allows for creative finishing options such as staining or painting. Noteworthy benefits include its distinct appearance, environmental friendliness due to recycled materials, and versatility for a range of applications.

However, users should be mindful of WoodFill's abrasiveness, recommending the use of a hardened nozzle. Calibrating the printer is crucial due to its potential difficulty in extrusion compared to PLA, and prints may be more brittle, requiring careful handling. Additional information includes the availability of various colors and alternative wood-based filaments in the market, providing users with choices based on their preferences. In summary, ColorFabb WoodFill stands out as an excellent option for those desiring natural-looking 3D prints, offering unique aesthetics, environmental consciousness, and versatility, albeit with considerations for handling and printing adjustments.

Filamentum Timberfill

Filamentum Timberfill, a PLA and natural spruce wood fiber composite, offers the practicality of PLA coupled with the warmth and natural appeal of real wood. Its wood-like finish, visible grain, and varied tones enhance its aesthetic, making it suitable for both functional and decorative prints. Timberfill maintains some flexibility, eases the printing process, and allows versatile finishing options. Its unique natural look, eco-friendly composition with recycled wood fibers, versatility, and ease of use make it an excellent choice for 3D printing. While considerations include potential abrasiveness, brittleness, and a slightly higher cost than standard PLA, the overall benefits position Timberfill as a worthwhile and distinctive filament for diverse projects.

The aesthetic appeal of Timberfill is noteworthy, producing prints with a striking wood-like finish that incorporates visible grain and even a subtle wood aroma. Its versatility extends with various natural wood tones, such as Oak, Mahogany, and Walnut, providing users with options for realistic and customized prints. While its strength aligns with PLA, making it suitable for a range of applications, Timberfill maintains some flexibility, albeit slightly less than pure PLA. Printing with Timberfill is user-friendly, sharing similarities with PLA settings, and its compatibility with finishing techniques like sanding, staining, painting, or varnishing adds to its appeal.

Polymaker PolyWood

PolyMaker PolyWood is a pioneering 3D printing filament developed by Polymaker, designed to replicate the appearance and feel of wood while addressing common issues found in traditional wood-filled filaments. This unique filament is exclusively composed of PLA, employing Polymaker's innovative Jam-Free™ and Stabilized Foaming™ technologies. Notably, PolyWood avoids the use of actual wood powder, mitigating the risk of nozzle clogs and enhancing overall printing reliability. It boasts a genuine wood aesthetic with visible grain patterns and a subtle wood scent.

Key features include the Jam-Free™ technology, ensuring smooth printing without nozzle clogs, and the Stabilized Foaming™ technology, providing a consistent and lightweight material with excellent layer adhesion and minimal warping. PolyWood is compatible with most standard 3D printers, accommodating PLA settings for temperatures ranging from 190°C to 210°C. Additionally, it allows for easy finishing processes like painting and staining, mimicking the characteristics of real wood and offering further customization options. Its slight flexibility makes it suitable for certain functional applications, and the filament is crafted from sustainable PLA plastic, aligning with eco-friendly practices.

eSun

eSUN, a prominent player in the 3D printing industry, offers an array of materials, including their noteworthy Wood PLA filament. Distinguished by an "active foaming technology," this filament replicates wood's texture without actual wood particles, ensuring a high success rate and precise finishes. With a relatively low price point, it becomes an ideal choice for experimenting with wood-like textures in diverse projects, from art pieces to toys. The Wood PLA boasts ease of printing, affordability, and eco-friendliness with its recycled wood content. However, it may lack the authentic feel of pure wood filaments and exhibit slightly weaker strength than traditional PLA, potentially experiencing stringing issues.

eSUN's Wood-based Filaments, exemplified by the Wood variant, present a more authentic wood look and feel due to a composition of PLA and various wood materials. While delivering highly realistic wood aesthetics and greater strength, these filaments pose increased challenges in terms of printability, demanding specific settings, and a hardened nozzle. The choice between Wood PLA and Wood-based Filaments hinges on the balance between ease of printing and the desire for authenticity, with the latter potentially being a more challenging yet visually rewarding option. Overall, eSUN's Wood Filaments provide a versatile and cost-effective solution for achieving wood-like textures in 3D prints, catering to a range of creative projects.

Fiberlogy

FiberWood, a creation of Fiberlogy, emerges as a standout wood PLA filament for 3D printing enthusiasts. With five color options, including those with a more natural appearance, FiberWood is the go-to choice for crafting wood-like toys, containers, and models. Noteworthy features include a composition of 70% PLA and 30% recycled wood fibers, providing a subtle wood grain texture and matte finish. Despite its slight deviation in wood feel compared to pure wood filaments and a marginally weaker strength than PLA, FiberWood compensates with its eco-friendly attributes and an enjoyable "woodshop" scent during printing.

For users prioritizing ease of printing and cost-effectiveness, FiberWood emerges as a top choice within the Fiberlogy wood filament lineup. However, for those placing a premium on authentic wood aesthetics and realism, the more challenging yet visually rewarding EasyWood might be the preferred alternative. One of FiberWood's strengths lies in its printability, maintaining an impressive diameter tolerance of ±0.02 mm, reducing the likelihood of hot end clogs. While being fairly easy to print, FiberWood may require a slightly higher bed temperature than standard PLA, as suggested by Fiberlogy's printing recommendations (70 °C).

Is 3D filament suitable for functional prints?

Certainly! However, 3D wood filament is great for creating objects you can use, such as tools or functional parts for things like home projects. The material is strong enough to handle practical tasks, making it a versatile choice beyond just decorative items.

What printers are compatible with 3D filament?

Most regular 3D printers can use 3D wood filament. Just check the temperature settings and guidelines from the filament’s instructions to make sure your printer can handle it. It’s like ensuring your oven is set to the right temperature for baking – you want everything to match up for the best results!

Conclusion

In exploring the landscape of wood 3D printer filaments, the highlighted options, including eSUN, ColorFabb, and Amolen, offer distinctive features. Each brand brings something special, from eSUN’s cost-effective experimentation opportunities to ColorFabb’s authentic wood aesthetics and Amolen’s fusion of PLA with finely ground bamboo. But choosing the “best” filament becomes a nuanced decision shaped by individual requirements. If your focus is on budget-friendly exploration, eSUN provides an attractive option. ColorFabb delivers an authentic wood-like finish, while Amolen combines PLA ease with a unique bamboo twist.

Considerations such as ease of use, visual appeal, budget constraints, and technical support availability play pivotal roles in determining the most suitable filament for your needs. This diverse array of filaments has garnered acclaim in various aspects. Still, the optimal choice ultimately lies in aligning these attributes with your specific projects and preferences in the dynamic realm of 3D printing. Happy crafting!