Have you ever wondered how to create cool, flexible objects with your 3D printer? Well, that’s where flexible filaments come into play! These materials, like thermoplastic polyurethane (TPU), mix the best of rigid plastic and rubbery goodness. Stretching and twisting your 3D prints without them breaking – that’s the magic of flexible filaments!

In this simple guide, we’ll explore what flexible filaments are, why they’re awesome, and how even beginners can join the fun of making bendy creations with their 3D printers. Let’s dive into the world of flexibility and discover the exciting possibilities it brings to your 3D printing journey.

What will you see here?

Introduction to Flexible 3D Printer Filament

Flexible 3D printer filaments, the superheroes of 3D printing, blend hard plastic’s toughness with rubber’s stretchiness, creating a magical mix known as a thermoplastic elastomer (TPE). This unique combination allows these materials to bend, stretch, and twist without breaking, making them perfect for printing functional and dynamic objects.

Whether you’re a seasoned pro or a 3D printing newbie, these filaments open up a world of possibilities, from crafting prototypes with flexible features to designing custom tools. Picture a 3D-printed object that can stretch like a rubber band or bend like a twisty straw – that’s the fascinating flexibility these filaments bring to your creations. In this journey into the realm of flexibility, we’ll explore the wonders of flexible filaments, making the seemingly complex world of 3D printing simple and accessible to all, proving that adding a touch of bendiness to your prints is within everyone’s reach. Get ready to make 3D printing a whole lot more exciting.

Types of Flexible Filaments

Diving into the realm of 3D printing brings us to a fascinating array of flexible filaments, each with its unique properties and applications. Let’s unravel the mysteries of the five most common types, opening the door to a myriad of possibilities for your next 3D printing project.

Thermoplastic Polyurethane (TPU)

Known as the powerhouse of flexible filaments, TPU stands out for its versatility. Highly elastic, durable, and abrasion-resistant, TPU boasts a wide range of shore hardness options, from 70A to 95A. Its exceptional oil and chemical resistance make it a top choice for crafting gaskets, seals, wearables, phone cases, footwear, RC tires, and sports equipment.

Thermoplastic Elastomer (TPE)

Offering a diverse range of shore hardnesses (from 30A to 95A), TPE presents a flexible alternative to TPU. With good printability and options for oil and chemical resistance, TPE finds its applications in grips, toys, prosthetics, and other softer uses similar to TPU.

Soft PLA

If affordability and ease of printing are your priorities, Soft PLA enters the scene. While moderately flexible with a lower shore hardness (around 40A), it delivers good impact resistance. This makes it an excellent choice for crafting phone cases, simple gaskets, cosplay props, and educational models.

Thermoplastic Polyamide (TPA)

Blending the strengths of nylon and TPE, TPA offers high strength, chemical resistance, and good flexibility. Although it requires a higher printing temperature compared to other flexible filaments, it’s an ideal choice for functional parts demanding both strength and flexibility. Applications include automotive parts, industrial tools, and sporting goods.

Polyether Block Amide (PEBA)

Recognized for its excellent flexibility and elasticity within a range of shore hardnesses (30A to 80A), PEBA excels in applications requiring tear strength and chemical resistance. While slightly more challenging to print, it finds its place in crafting medical devices, prosthetics, footwear, and sports equipment.

In summary, flexible 3D printing filaments offer a spectrum of choices for creators and engineers alike. From the powerhouse TPU to the adaptable TPE, the budget-friendly Soft PLA, the versatile TPA, and the resilient PEBA, each filament type brings its own set of strengths and applications. Understanding these options allows you to unleash your creativity, turning your 3D printing endeavors into a flexible and dynamic journey. So, what will you create with the endless possibilities these filaments offer? The choice is yours!

Benefits of Using Flexible Filaments

Embracing the benefits of flexible 3D printing filaments goes beyond mere material choices; it opens up a world of creative and practical possibilities, transforming the way objects are designed, manufactured, and utilized across various industries.

Enhanced Functionality for Dynamic Designs

Flexible 3D printing filaments usher in a new era of design possibilities by enabling the creation of objects with features unattainable with rigid materials. Living hinges allow for intricate movements within printed parts, while soft and ergonomic grips and handles enhance user comfort. Additionally, the ability to produce watertight seals, gaskets, and shock-absorbing components adds a layer of versatility, making flexible filaments ideal for dynamic and functional designs.

Exceptional Material Properties

The material properties of flexible filaments contribute significantly to their appeal. Notably, these filaments exhibit great elasticity, allowing for stretching, bending, and twisting without sacrificing structural integrity. Their impact resistance makes them durable in wear-and-tear scenarios, and their vibration-dampening capabilities find applications in machinery components. Some filaments also offer chemical resistance, making them suitable for diverse industrial and practical uses.

Broadened Application Range

Flexible filaments expand the horizon of 3D printing applications across various industries. From crafting wearables like straps, watch bands, and phone cases to developing functional prototypes with realistic movement, these filaments prove versatile. They find utility in the medical field for creating prosthetics, orthotics, and surgical tools, as well as in sports equipment, automotive parts, and consumer goods, showcasing their adaptability across a wide spectrum of products.

Additional Advantages for Seamless 3D Printing

Beyond their functional benefits, flexible filaments offer additional advantages that simplify the 3D printing process. The ability to reduce complexity by consolidating multiple parts into a single flexible component streamlines designs. Moreover, customizable properties, such as different shore hardness options, provide a range of flexibility and stiffness for tailored applications. The lightweight nature of these filaments adds another layer of convenience, especially advantageous in scenarios where weight is a critical consideration.

Printing Techniques and Settings

Printing with flexible filaments might seem a bit tricky, but fear not – we’ve got your back! Here’s a quick guide with easy-to-follow techniques and settings to make your flexible 3D printing experience smooth and successful.

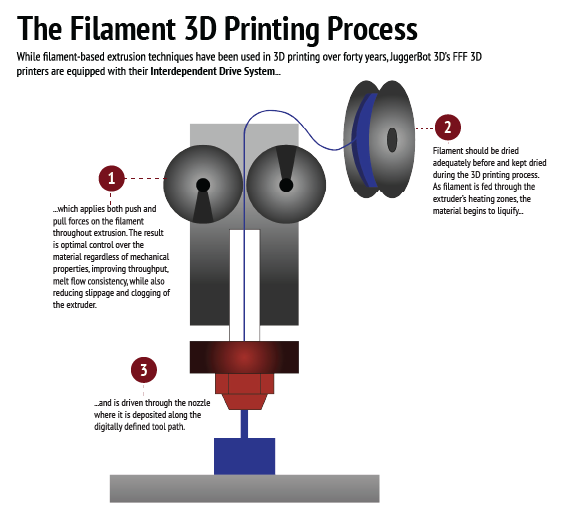

Printing Techniques

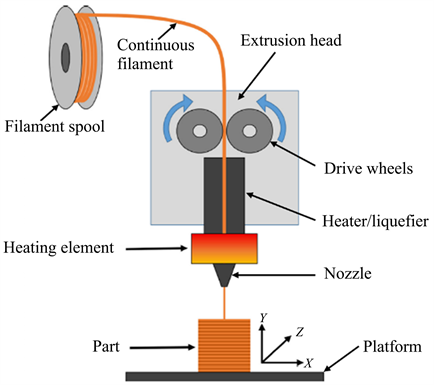

1. Direct Drive Extruder: Go for this if you can! It helps prevent those pesky jams flexibles love to cause in Bowden setups. Direct drive gives better control by sending the filament straight to the nozzle.

2. Slow and Steady Wins: Keep your print speeds slow, around 15-20 mm/s. Speed demons might cause your filament to get all squished and lead to jams – not fun!

3. Retraction or No Retraction: Retraction pulls the filament back, but flexibles don’t like that. Try turning it off or using just a tiny bit to avoid stringing troubles.

4. Z-Hop: Give your nozzle a little lift during travel to stop strings from forming between your printed lines.

5. Skirts and Brims: Start your prints with these lines – they help get your nozzle ready and improve that all-important first layer.

6. Cooling Fan Caution: Flexibles don’t need too much cooling love. Keep that fan on the down-low or even turn it off, as these materials cool down quickly.

Settings:

1. Extruder Temperature: Aim for 210-250°C, depending on your filament brand. Start a little high and tweak down if things get oozy.

2. Bed Temperature: Keep it cozy at 40-60°C for good adhesion. Check the filament rules; some might have specific temperature preferences.

3. Layer Height: Stick to 0.2-0.3mm for smooth sailing. This helps your extruder stay cool and reduces pressure.

4. Flow Rate Fun: You might need a slight flow rate tweak (around 5-10%) to keep that material flowing just right.

5. Combing Champion: If you ditched retraction, combing can be your string-fighting sidekick. It helps keep things tidy between layers.

Now armed with these simple tips, you’re ready to dive into the flexible filament world and bring your 3D prints to life. Happy printing!

Comparative Analysis of Popular Flexible Filaments

Exploring the diverse landscape of flexible filaments provides valuable insights into each material’s unique characteristics, making it essential for creators to make informed choices. Let’s delve into the details of the popular flexible filaments presented in the table:

| Filament | Material | Characteristics | Printing Ease | Cost |

|---|---|---|---|---|

| TPU (Thermoplastic Polyurethane) | Polyester and polyurethane mix | Super elastic (70A-95A), durable, great for wearables and phone cases | Moderate | A bit pricier ($$), versatile use |

| TPE (Thermoplastic Elastomer) | Various blends | Variable elasticity (30A-95A), moderate durability | Moderate | Wallet-friendly ($ – $$), toys and grips |

| Soft PLA (Polylactic Acid) | Modified PLA | Moderate elasticity (40A), easy printing | Easy peasy | Budget-friendly ($), great for educational models |

| TPA (Thermoplastic Polyamide) | Nylon and TPE blend | High elasticity (60A-85A), durable, demanding but worth it | A bit demanding | A bit steep ($$$), ideal for industrial tools |

| PEBA (Polyether Block Amide) | Polyamide and polyether blend | Excellent elasticity (30A-80A), high durability | Moderate | Mid-range ($$), medical devices and prosthetics |

Innovations in Flexible Filament Technology

Flexibility in 3D printing is leaping into the future with groundbreaking innovations that promise to reshape the way we create. Here’s a sneak peek at the exciting developments on the horizon.

Multi-material Marvels

Imagine a single filament with the power to bring both softness and rigidity to your prints. Multi-material filaments are emerging, allowing creators to craft objects with different flexibility levels in various areas. Picture a phone case with a soft, grippy bumper and a sturdy backplate, all from the same spool – a true game-changer in design possibilities.

Dynamic Foaming Wonders

Enter the era of lightweight and compressible prints. Dynamic foaming filaments expand under controlled conditions during printing, offering many opportunities for creating footwear, cushioning, and sports equipment that is significantly lighter without compromising on strength.

Conductive and Magnetic Magic

Flexible filaments are getting a tech upgrade with the integration of conductive or magnetic properties. This opens doors to interactive toys, wearable electronics, and smart clothing that respond to movement or magnetic fields, bringing a touch of magic to the world of 3D printing.

Shape Memory Marvels

Filaments that “remember” their original shape and can return to it under specific stimuli, such as heat or light, are becoming a reality. This innovation enables self-deploying structures, adaptable clothing, and temperature-responsive medical devices, showcasing the transformative potential of shape memory technology.

Biocompatible and Sustainable Shift

The push towards a greener and more biocompatible future is evident in the development of flexible filaments made from bio-based or recycled materials. Researchers are also exploring the possibility of filaments compatible with human tissue, opening up new horizons in prosthetics and medical implants.

Beyond Materials

In addition to material innovations, advanced printing techniques and software tools are in the spotlight. Multi-extrusion printing and bioprinting for flexible filaments are being explored, promising more intricate and customized designs. Meanwhile, improved software tools are simplifying the printing process, making it more accessible and reliable.

The future of flexible filament technology is not just about materials; it’s about expanding possibilities, breaking boundaries, and creating a more sustainable and interconnected world. It’s an exciting journey into the unknown, where each innovation opens up a realm of possibilities for the ever-evolving field of 3D printing.

What is the difference between PLA and ABS?

PLA filament is the superhero of 3D printing, the eco-friendly Avenger! It’s like a magic material that’s kind to the environment and super easy for anyone to use. But, watch out, it might not be the strongest hero out there. Now, meet ABS filament, the Hulk of 3D printing materials! It’s tough, it’s strong, but it’s not as eco-friendly as our friendly Avenger, PLA. ABS likes a warm bed when it’s printing, and it’s perfect for those projects that need some serious muscle.

So, if you’re into saving the planet with an easy-breezy vibe, go for PLA, the superhero next door. But, if your 3D printing adventure needs some serious strength, ABS, the Hulk, might be the hero you’re looking for! Choose your printing superhero wisely!

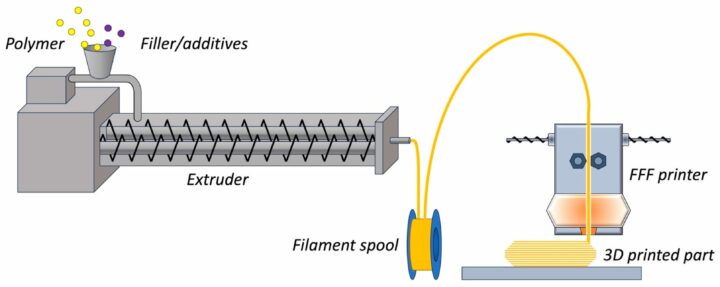

What is the purpose of adding additives?

Adding additives to filaments is like giving them a superpower boost for specific tasks. Imagine your regular 3D printing material as a superhero, and additives are the special gadgets in their utility belt. These additives can enhance features like strength, and flexibility, or even add cool effects like glow-in-the-dark abilities. It’s like customizing your superhero to tackle different challenges. Want your printed object to be super strong? Add some reinforcing fibers! Need it to shine in the dark? Toss in some glow-in-the-dark particles! So, these additives are like the secret ingredients that turn an ordinary filament into a versatile superhero ready to tackle any 3D printing mission!

Conclusion

In conclusion, flexible filaments bring a touch of magic to your 3D printing journey. They blend the toughness of hard plastic with the stretchiness of rubber, allowing you to create cool, bendy objects with your 3D printer. From superheroes like TPU to the versatile TPE, budget-friendly Soft PLA, demanding but robust TPA, and resilient PEBA, each filament type has its strengths and applications.

But the excitement doesn’t stop there! The future holds even more wonders with multi-material marvels, dynamic foaming wonders, conductive and magnetic magic, shape memory marvels, and a shift towards biocompatible and sustainable filaments. These innovations promise to revolutionize the way we create, making 3D printing more versatile, interactive, and environmentally friendly.

Whether you’re a seasoned pro or a 3D printing newbie, the world of flexibility is open to all. With simple techniques and settings, you can dive into the flexible filament world and bring your creations to life. So, what will you make with these endless possibilities? The choice is yours – happy printing!